Single-phase Immersion Cooling with GIGABYTE

Reliability, availability, and serviceability are all traits found in the best data centers of today and tomorrow. As IT hardware and technology continue to improve, they are also making it tough for current data centers to be sustainable with the traditional fans, HVAC, and hot/cold aisles.

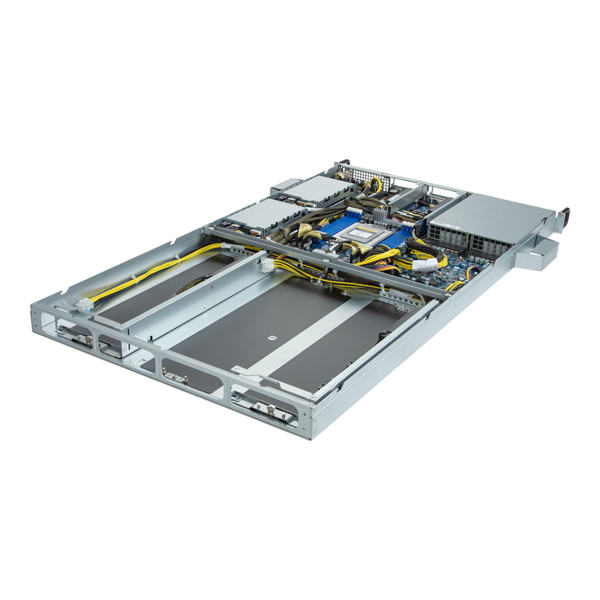

Why? A major reason - increase in rack power density. For each new generation of chips, the die size is shrunk while the number of transistors has increased, and this translates to higher performance, but also more heat. For instance, a GPU dense server can support CPUs and GPUS up to 300W TDP each component, but new generations of hardware are increasing the TDP by 25% or more, which is unsustainable in the same footprint. Consequently, servers are reaching thermal limitations. To maintain the same hardware density, a more efficient cooling approach is needed.

Data center architects realize this and quantify this efficiency using power usage effectiveness (PUE). PUE is a ratio that compares how much power enters the data center to the power delivered to IT equipment. Ideally, the PUE value would be 1.0; however, traditional air-cooled data centers achieve a PUE of ~1.65, which isn’t horrible, but it shows room for improvement. Single-phase immersion cooling can achieve a PUE in the ballpark of 1.02-1.03.

How it Works

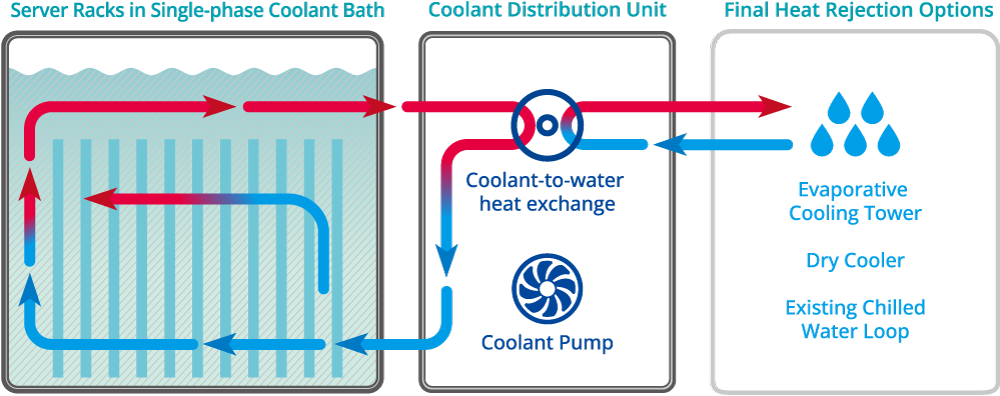

Single-phase immersion cooling redefines the data center from how IT equipment is cooled to the reduction in the amount and complexity of the data center infrastructure. By submerging IT equipment into a dielectric liquid bath, heat is removed faster than air while no damage or degrading occurs to all components. The liquid coolant with a higher specific heat capacity than air can quickly remove the heat. The heat given off by CPUs, GPUs, and other components is transferred directly to the liquid or via a heatsink. The warm liquid is then pumped out by a coolant distribution unit (CDU) or dry cooler. In the CDU cases, a second transfer occurs as the heat is then transferred to facility water. The resulting cooled coolant is pumped back into the immersion tank while the warmed water continues on to a heat exchanger to be expelled. And the cycle continues. Also, as the name implies, the fluid in the immersion tank does not change state, so there is no evaporation or condensation occurring, which ensures operator safety and allows for easy servicing of the tank and IT equipment.

Data centers are heating up. High performance and AI workloads demand a level of compute density that we haven't seen before. The power requirements demanded by modern server processors, such as AMD EPYC and Intel Xeon Scalable, has more than doubled in a decade. Adding to this, accelerators have made great progress in data analytics and AI, but they too add to the power envelope in such a way that the data center just can't keep up. It's time to go back to the drawing board to create a new design.

GIGABYTE aims to give customers a hub to design and acquire all the necessary technology to deploy a single-phase immersion cooling data center. As a leader in enterprise technology, GIGABYTE has the ability to leverage current server designs to accommodate new specialized servers for immersion cooling deployments in tanks provided by GIGABYTE or its other global immersion partners. The first wave of immersion ready servers came as a result of customers' requests so it's best to contact a GIGABYTE sales representative to start the path to joining the immersion era.

Accessories and Coolants

GIGABYTE provides accessories specifically designed for its Single-phase Immersion Cooling Solution to simplify deployment. Along with the verified coolant, the complete IT solution ensures it is safe, efficient, and easy to use even for new adopters.

IT Lift

- Dimension: W 1.15 x D 0.85 x H 1.53 m

- Unit weight: 200 kg

- Lifting load: 70 kg

- Input power: 100-240Vac~, 50/60Hz, 3.5A

IT Dry Rack

- Dimension: W 1.23 x D 0.63 x H 1.25 m

- Unit weight: 75 kg

- Support size: EIA 19” & OCP 21” compatible

- Server depth supported: 900 mm

- Support space: 20 U or 20 OU

- Load capacity: 800 kg

Coolants

- Shell: Immersion Cooling Fluid S3 X, Immersion Cooling Fluid S5 X

- Exxon Mobil: SpectraSyn™ 6

- Chevron: SynFluid® PAO 4 cST

*Recommended coolant varies depending on regions. Please contact local sales for details.