Cooling

GIGABYTE Deep Dive: How We Built Our Industry-leading Liquid Cooling Solution

In "GIGABYTE Deep Dive", we invite our in-house experts to draw back the curtains on the industry-leading innovations that deliver best-in-class computing solutions to our enterprise clients. Today, we are excited to interview our server cooling team and talk about the three "customer-centric insights" that propelled the creation of GIGABYTE Technology's all-in-one DLC solution.

Direct Liquid Cooling Brings Exponential Returns in the Long Term

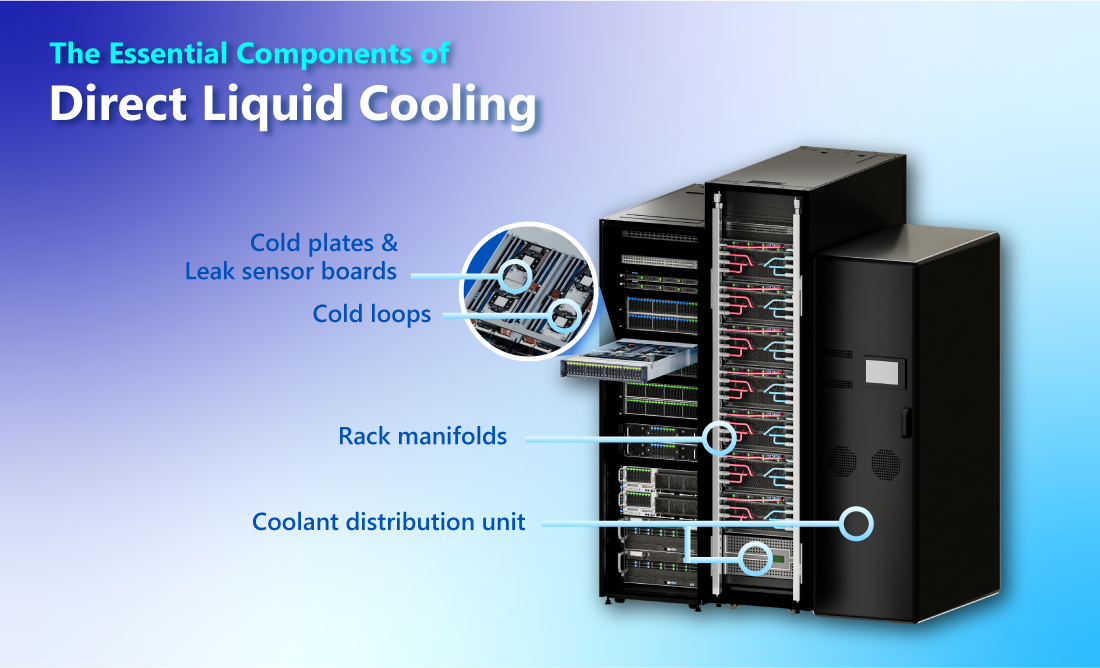

Introducing liquid cooling to your server rack means the addition of many new components. Despite the entry barrier, liquid cooling is the new growth engine in the age of AI thanks to greater compute performance, better sustainability, and lower cost in the long term.

GIGABYTE's First Step is Understanding the Customer's Actual Needs

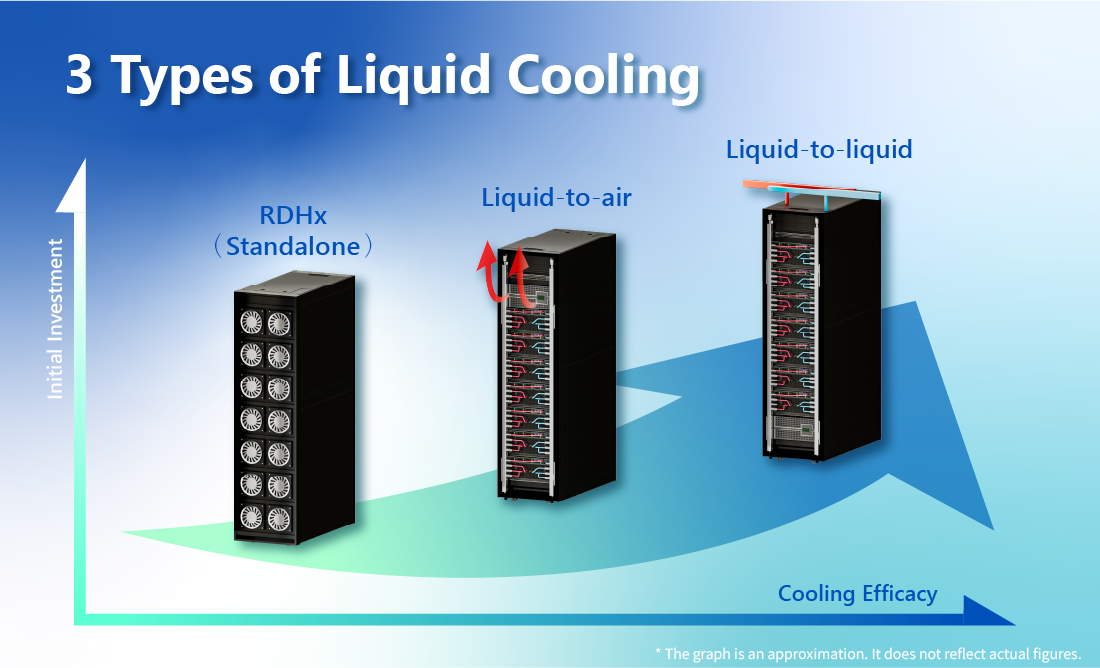

GIGABYTE can recommend different types of liquid cooling based on client preference. This graph gives a general idea of the cooling efficacy of different methods versus their initial investment.

Design and Manufacturing Expertise is Key to Building an Ideal DLC Solution

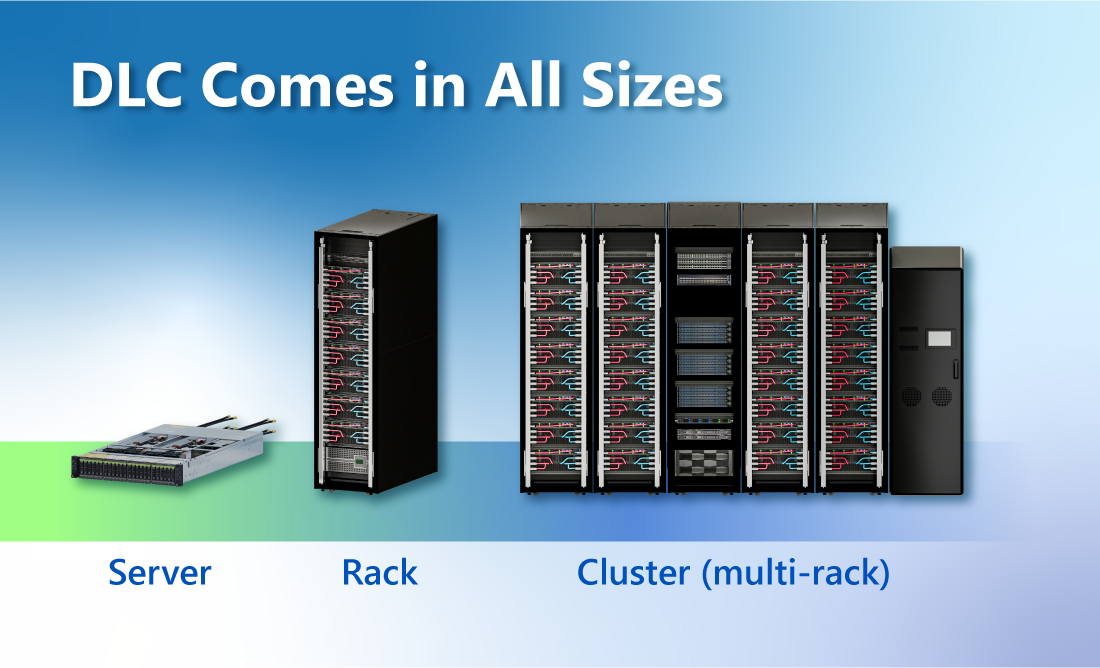

GIGABYTE doesn't just sell DLC products, but total solutions that encompass everything from a single server to a server rack to a cluster built out of multiple racks. With such a broad range of options, any client will be able to find their most suitable solution.

Value Chain Leadership Ensures Best-in-class Support for Our Customers

At a glance, these are the three major ways you stand to benefit when you take the first step into the world of advanced cooling. As more and more companies adopt liquid cooling, it is becoming mainstream—even mandatory—for modern AI & HPC data centers.

GIGABYTE Goes the Extra Mile to Deliver Customer Satisfaction

Get the inside scoop on the latest tech trends, subscribe today!

Get Updates

Get the inside scoop on the latest tech trends, subscribe today!

Get Updates