| 2009 | |

|---|---|

|

|

| 2010 | |

|---|---|

|

|

| 2011 | |

|---|---|

|

|

| 2012 | |

|---|---|

|

♦ Presented with the "Industrial Sustainable Excellence Award" by the Industrial Development Bureau of Ministry of Economic Affairs • Developed sustainable supply chain evaluation to expand our efforts in CSR, environmental protection, labor rights, fair trading practices, supply chain responsibility as well as contributions to society and local community so everyone can work together for a sustainable future • Introduced waste electronics recycling regardless of brand at each customer service site to reduce the burden on the environment and the threat to the environment/ecology |

| 2013 | |

|---|---|

|

♦ Received Energy Saving and Carbon Reduction Label from EPA in the office category • Hosted the Green Innovations event with sustainability, innovation and value as the theme to lay the foundations for sustainability • Pioneered the G-Home Sustainable Eco-roof on the corporate headquarters to promote the ideals of sustainability and environmental education based around planting trees for the planet and promoting employee health • Set up the GIGABYTE Go Green Club, a corporate volunteering group dedicated to helping the environment and society • Launched Working Holiday so employees can do their part and protect their homeland directly. |

| 2014 | |||

|---|---|---|---|

|

♦ Received Commonwealth CSR Award (Large Corporation Top 18) and TCSA Climate Leadership Award

♦ Received New Taipei City Environmental Education Award (private corporation category – excellent award) • Hosted the Seeing Green series of activities - Family trips, family painting competitions and eco-themed photography competition instilled the philosophy of ecology and sustainability in everyday life. • Hosted the "Symposium on Reducing Operating Risks and Resource Waste in the Green Supply Chain" to strengthen product responsibility and partner with suppliers for a win-win outcome. • Partnered with Green Share for promoting the GMCP green cloud platform to reduce the risk of hazardous substance management, enhance management efficiency, respond to future regulatory trends and host green cloud supplier conferences so everyone can work together to protect the environment. |

||

| 2015 | |

|---|---|

|

♦Received National Environmental Education Award (private corporation

category – outstanding award)

♦ Selected as one of the top 30 companies in Taiwan by the GVM's CSR Survey. • Supporting legislation on rooftop greening to establish urban eco-corridors, reduce the urban heat island effect, alleviate peak power consumption during the summer and lower the demand for nuclear power. • Launched the “Thousand Mile Trek – Go Green Taiwan” program.Volunteers will walk in relays over 5 years to walk their dream, pick up plastic waste, and discover the natural and cultural beauty of Taiwan. |

| 2016 | |

|---|---|

|

♦Presented with the “Sports Enterprise Certification” by the Sports Administration of Ministry of Education. ♦Selected as one of the top 40 companies in Taiwan by the GVM's CSR Survey. ♦Received the Commonwealth Top 50 CSR Award (rank 32nd in Large Corporation group) • Organized "Protect our Oceans - Plastic Reduction Poster Design Competition” to promote plastics reduction and co-learning with the environment and society • Introduced return on social investment assessment (SROI) for “G-HOME Sustainable Eco-Rooftop” and “Thousand Mile Trek - Go Green Taiwan” programs to determine the projects’ influence on society |

| 2017 | |

|---|---|

|

♦ Awarded Role Model Award of the GVM’s CSR Survey - Electronics and Technology Industry ♦2017 TCSA Taiwan Corporate Sustainability Award - Climate Leadership Award, TOP50 Taiwan Corporate Sustainability Awards, Golden Award of the TOP50 Corporate Sustainability Awards ♦2017 SGS Taiwan ISO 14001 Plus - Environmental Performance Management Model Award ♦2017 Common Wealth Magazine Corporate Citizenship Award (No. 18 among large corporations) ♦2nd Place of 2017 Fine Nursery Room- Baby-Friendly Group by Department of Health in Taoyuan City ♦2017 Golden Pin Design Award - AORUS X7 using eco-friendly packaging materials made of Recycle Fiber of Plant (RFP) • Outstanding Blood Donation Group awarded by Taiwan Blood Services Foundation • Launched “Make Earth Green Again” in cooperation with the Plant-for-the-Planet Foundation in Germany, and committed to planting 75,000 trees in 3 years. • Held “Reduction, Sharing, Love for Earth - Friendly Product Design Competition” to encourage university/college students to show their ideas about sustainability and creative design |

| 2018 | |

|---|---|

|

♦GVM’s CSR Award - Top 5 of Electronics and Technology Industry and Top 6 Educational Promotion Action Plan ♦2018 TCSA Taiwan Corporate Sustainability Award - Climate Leadership Award, TOP50 Taiwan Corporate Sustainability Awards ♦ 2018 Common Wealth Magazine Corporate Citizenship Award (No. 21 among large corporations) ♦Taoyuan Department of Health Outstanding Breastfeeding Rooms Program - Gold Award ♦2018 iF Product Design Award - AORUS X7 using eco-friendly packaging materials made of Recycle Fiber of Plant (RFP) ♦Sports Administration by Ministry of Education: Exercise Enterprise Certification • The impact of “Make Earth Green Again” program, cooperated with the Plant-for-the-Planet Foundation, kept expanding and had trained more than 200 Climate Justice Ambassadors in Taiwan • Held the first Suppliers Conference themed “Reduction, Sharing, Love for the Earth” to call on suppliers to join the line of reducing CO2, water, waste, and tree planting. • Launched No Trace Diet program that completely prohibits plastics at staff canteen of Headquarters • Continued to publish the “Product Environmental Report” for key products on the Sustainability website that disclosure the level of product impact in the three aspects of climate change, air quality and ecology. |

| 2019 | |

|---|---|

|

♦ GVM’s CSR Survey - Top 5 of Electronics and Technology Industry ♦ 2019 Common Wealth Magazine Corporate Citizenship Award (No. 33 among large corporations) ♦ Excellent Enterprise Award in Taoyuan City - Happy Enterprise Award ♦ Group Award of Social Education Contribution Awards by the Ministry of Education ♦ Health Workplace Certification by the Health Promotion Administration ♦ Nanping factory presented with Model Business of Maternal Health Guardian Alliance and Innovation Award of Drug Abuse Promotion by the Food and Drug Administration • Launched the Sustainability Fund program to turn the saving cost from reduction into green innovation budget for encouraging internal green power • Kept deepening and expending the No Trace Diet program to include collaboration with and education for surrounding shops and to build an eco-friendly life circle • Released a new version of the Product Environmental Report with disclosure of 12 environmental impact aspects to fulfill our responsibility as a producer • Completed Holding 5 Plant-for-the-Planet Academies in Taiwan that cultivated 405 Taiwanese Climate Justice Ambassadors, Also, sponsored the hosting of 15 Plant-for-the-Planet Academies in developing countries that trained 962 Climate Justice Ambassadors. |

| 2020 | |

|---|---|

|

♦ GVM’s CSR Survey - Role Model Award of Electronics and Technology Industry, and TOP 7 of Environmental Protection Project ♦ 2020 Common Wealth Magazine Corporate Citizenship Award (No. 26 among large corporations) • Fulfilled our promise to “Make Earth Green Again” by planting 75,000 trees and donating 16,000 trees to business partners and consumers • Supported quarantine efforts by partnering with distributor Weblink to launch notebook leasing plans for home or tele-work use that prevent contagious infection between employees |

GIGABYTE has always set an example of honesty and practicality. We possess sound business management, sales channels and comprehensive customer service, continue to achieve innovative brand and technology, provide customers with excellent value, and receive strong support and recognition from international awards and the media. We also have stable growth in operation. We distributed 2018 annual surplus in 2019 that each common stock is paid a dividend of NTD 3.05 per share. GIGABYTE will continue maintain corporate stability and sustain prosperous development through dividend distribution and reasonable retained earnings. For detailed information, please refer to the relevant financial information disclosure on the 2019 GIGABYTE Annual Report. (More)

A Healthy and Diversified Workplace

GIGABYTE upholds the philosophy of “Upgrade Your Life”, where we abide by the government's Labor Standards Act and internationally recognized human rights (including the UN Universal Declaration of Human Rights and the ILO Declaration on Fundamental Principles and Rights at Work). We value employee communication and development. Therefore, we have established an employee message board and employee opinion email, where dedicated personnel will respond to any suggestion or opinion given by our colleagues. GIGABYTE is committed to providing comprehensive and diverse work-life balance measures by creating a friendly, safe and harmonious workplace environment and providing a GIGABYTE green-living lifestyle that balances work, life and recreation.

At the end of 2019, GIGABYTE and its subsidiaries employed 7,471 people with 85% of permanent and full-time employment. Temporary employment accounts for 15% (temporary employees hired to accommodate fluctuations in production peaks in factories in China, as well as trainees and temporary personnel hired under industry-academia collaboration programs at the Headquarters). The gender distribution of employees was 40.2% females and 59.8% males.

GIGABYTE upholds the philosophy of “Upgrade Your Life”, where we abide by the government's Labor Standards Act and internationally recognized human rights (including the UN Universal Declaration of Human Rights and the ILO Declaration on Fundamental Principles and Rights at Work). We value employee communication and development. Therefore, we have established an employee message board and employee opinion email, where dedicated personnel will respond to any suggestion or opinion given by our colleagues. GIGABYTE is committed to providing comprehensive and diverse work-life balance measures by creating a friendly, safe and harmonious workplace environment and providing a GIGABYTE green-living lifestyle that balances work, life and recreation.

At the end of 2019, GIGABYTE and its subsidiaries employed 7,471 people with 85% of permanent and full-time employment. Temporary employment accounts for 15% (temporary employees hired to accommodate fluctuations in production peaks in factories in China, as well as trainees and temporary personnel hired under industry-academia collaboration programs at the Headquarters). The gender distribution of employees was 40.2% females and 59.8% males.

Career Development Emphasizing Integrity and Skills

Employee learning and development is very important at GIGABYTE. In addition to cultivation of innovation and professional skills, enhancement of living aesthetics and cultural sophistication among employees are also an emphasis in terms of employee development. In 2019, GIGABYTE conducted a total of 83,888 hours of training. Education and training courses are tailored to each position that employees at manager level received a total of 72,962 hours of training while other employees at profession level received 10,926 hours in total.

Corporate Integrity Training:

Recruit Training

Ethical corporate management is a key GIGABYTE value. Recruits are given comprehensive education and training to ensure they understand the GIGABYTE “Code of Business Conduct.” All recruits shall take a 6-hour orientation course which includes topics of a basic introduction of GIGABYTE, brand vision, core competencies, health, and welfare. The sustainability and character-building course also cover integrity and sustainability, legal basics, green quality policy, and AEO policy. For workers in factories, the course also includes RBA education. Additional training courses are also provided for different roles and sites to ensure a smooth transition for newcomers. A total of 1,249 classes were conducted in 2019 to provide 14,074 trainees and 56,604 hours of training.

In-service Employee Training

We are continuing to host and introduce integrity-related business training for current employees. Different courses on internal audits and controls, accounting system, and ethical management are set up for managers, general employees, and foreign employees to ensure that every employee has a complete understanding of our integrity vision and system. A total of 32 classes were held in 2019 to provide 8,695 trainees and 3,907.5 hours of training.

Social Contribution to Promote Mutual Support and Digital Tolerance

"Care about society and sustainable development" define GIGABYTE's interactions with society. In 2002, we formed the GIGABYTE Education Foundation to promote technology education, arts and culture, aesthetics and create a harmonious and advanced society. In conjunction with GIGABYTE’s core competencies and corporate influence, we are devoted to promoting the welfare of people. In addition, we also encourage employees to be a part of the community through charity and social service. By making a difference with limited resources and giving back to society through tangible and sustained initiatives, GIGABYTE employees can make our surrounding communities a better place.

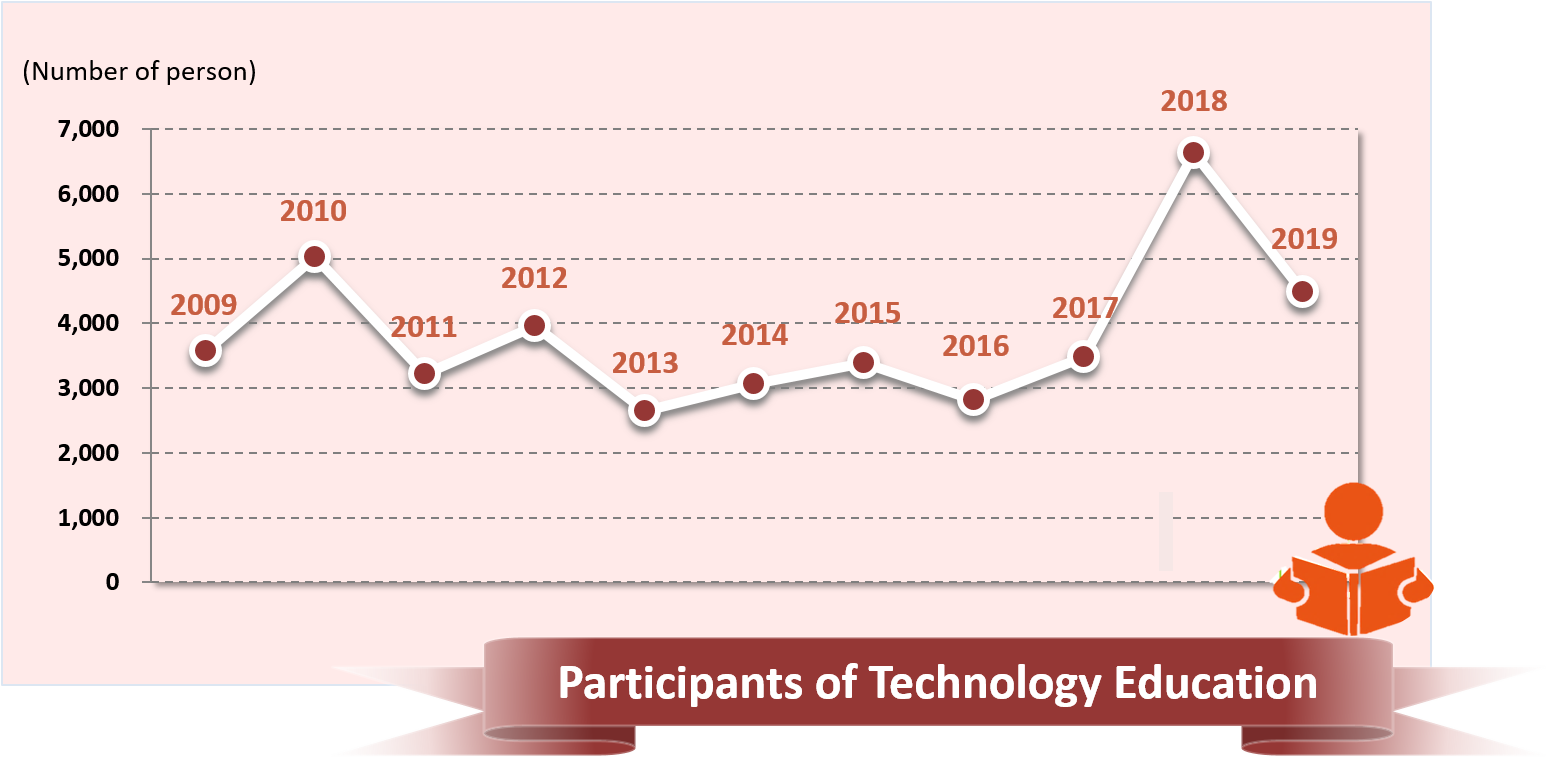

As a computer hardware manufacturer, GIGABYTE extends our influence in science and technology education based on our core values. We hope to shorten the science and technology gap between regions, generations and so on. GIGABYTE has been hosting the Secret to Learning Computers, PC-DIY Technology-on-campus events the Secret to Learning Computers, PC-DIY, technology-on-campus events and other courses since 2002. A new course Computer Doctor was introduced in 2019 with students given a tour to the RMA center of Bestyield International to learn about the circular economy and its “Mottainai” philosophy. Also, the GIGABYTE “Fun Play with IoT Summer Camp” taught children how to turn their digital imagination into reality through design thinking.

A total of 151 events have been held in 2019, benefiting 4,485 students and the accumulative number of participants since 2009 is 64,276.

Employee learning and development is very important at GIGABYTE. In addition to cultivation of innovation and professional skills, enhancement of living aesthetics and cultural sophistication among employees are also an emphasis in terms of employee development. In 2019, GIGABYTE conducted a total of 83,888 hours of training. Education and training courses are tailored to each position that employees at manager level received a total of 72,962 hours of training while other employees at profession level received 10,926 hours in total.

Corporate Integrity Training:

Recruit Training

Ethical corporate management is a key GIGABYTE value. Recruits are given comprehensive education and training to ensure they understand the GIGABYTE “Code of Business Conduct.” All recruits shall take a 6-hour orientation course which includes topics of a basic introduction of GIGABYTE, brand vision, core competencies, health, and welfare. The sustainability and character-building course also cover integrity and sustainability, legal basics, green quality policy, and AEO policy. For workers in factories, the course also includes RBA education. Additional training courses are also provided for different roles and sites to ensure a smooth transition for newcomers. A total of 1,249 classes were conducted in 2019 to provide 14,074 trainees and 56,604 hours of training.

In-service Employee Training

We are continuing to host and introduce integrity-related business training for current employees. Different courses on internal audits and controls, accounting system, and ethical management are set up for managers, general employees, and foreign employees to ensure that every employee has a complete understanding of our integrity vision and system. A total of 32 classes were held in 2019 to provide 8,695 trainees and 3,907.5 hours of training.

Social Contribution to Promote Mutual Support and Digital Tolerance

"Care about society and sustainable development" define GIGABYTE's interactions with society. In 2002, we formed the GIGABYTE Education Foundation to promote technology education, arts and culture, aesthetics and create a harmonious and advanced society. In conjunction with GIGABYTE’s core competencies and corporate influence, we are devoted to promoting the welfare of people. In addition, we also encourage employees to be a part of the community through charity and social service. By making a difference with limited resources and giving back to society through tangible and sustained initiatives, GIGABYTE employees can make our surrounding communities a better place.

As a computer hardware manufacturer, GIGABYTE extends our influence in science and technology education based on our core values. We hope to shorten the science and technology gap between regions, generations and so on. GIGABYTE has been hosting the Secret to Learning Computers, PC-DIY Technology-on-campus events the Secret to Learning Computers, PC-DIY, technology-on-campus events and other courses since 2002. A new course Computer Doctor was introduced in 2019 with students given a tour to the RMA center of Bestyield International to learn about the circular economy and its “Mottainai” philosophy. Also, the GIGABYTE “Fun Play with IoT Summer Camp” taught children how to turn their digital imagination into reality through design thinking.

A total of 151 events have been held in 2019, benefiting 4,485 students and the accumulative number of participants since 2009 is 64,276.

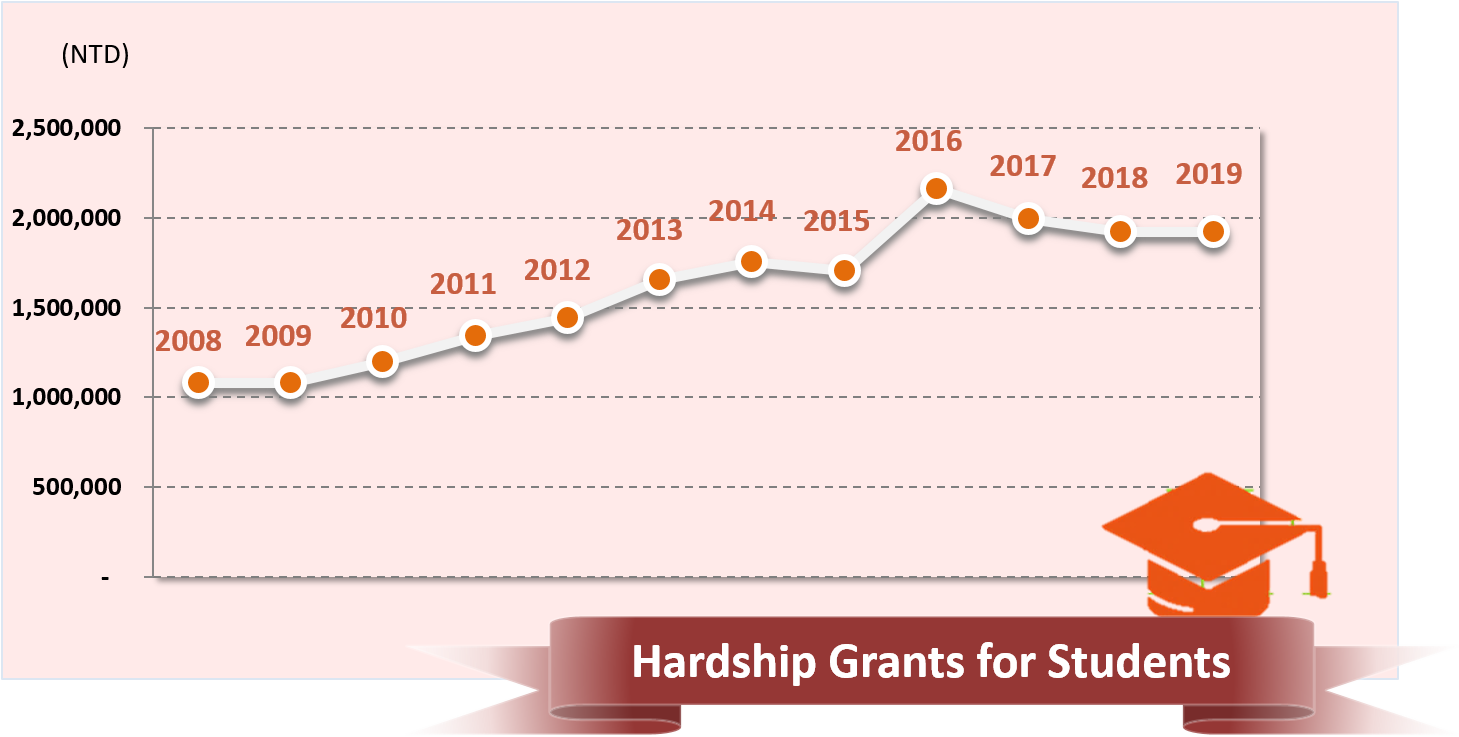

The GIGABYTE Benevolence - Hardship Grant for Students is a long-running program that invites employees to make fixed monthly or annual donations to children in disadvantaged families in order to reduce their economic stress. A total of 833 students and families experiencing hardship have received assistance since 2003.

Since the launch of Green Action Plan in 2009, GIGABYTE has been devoted to building employees’ environmental awareness in their work and life through a comprehensive and pragmatic approach. Environmental protection and sustainability should not be lofty topics but rather a kind of habit practiced every day. Over the past decade, the Green Action Plan has delivered a variety of services: knowledge-oriented activities such as seminars, workshops, and newcomer training; experience-oriented activities such as working holidays, a green volunteering club, drawing and photography contests; custom-oriented measures like vegetarian food promotion, waste reduction - which have effectively promoted employees to develop more sustainable lifestyles and cultivate their environmental protection concepts. For further detail, please refer to Sustainability and Environmental Education .

Besides the internal environmental education, the G-HOME GIGABYTE Sustainable Eco-Roof, founded in 2013, also promotes the benefits of rooftop greening by opening it to the external visitors. In 2017, G-HOME received the Environmental Education Facility and Field Certification from the Environmental Protection Administration. The two certificated environmental education courses. Rooftop Greening is not A Dream and The World is a Circle, are developed to promote the concepts of sustainability, co-prosperity, and zero waste to the public, industries, government, and academia. Moreover, we look forward to seeing more sustainable eco-roofs being constructed to make Taiwan greener and healthier. For further details about G-HOME Sustainable Eco-Roof, please refer to Environmental Education at G-HOME .

Besides the internal environmental education, the G-HOME GIGABYTE Sustainable Eco-Roof, founded in 2013, also promotes the benefits of rooftop greening by opening it to the external visitors. In 2017, G-HOME received the Environmental Education Facility and Field Certification from the Environmental Protection Administration. The two certificated environmental education courses. Rooftop Greening is not A Dream and The World is a Circle, are developed to promote the concepts of sustainability, co-prosperity, and zero waste to the public, industries, government, and academia. Moreover, we look forward to seeing more sustainable eco-roofs being constructed to make Taiwan greener and healthier. For further details about G-HOME Sustainable Eco-Roof, please refer to Environmental Education at G-HOME .

Greenhouse Gas Emissions

Total GIGABYTE greenhouse (GHG) emissions in the last two years were as follow:

• The organizational gross GHG emission (scope 1 and 2) in 2018 was 27,663.92 t-CO2e with the majority (97.6%) coming from scope 2 emissions. Comparing with the base year 2009, the emission level has cut 21,293.22 t-CO2e, equivalent to a reduction of 43.49%.

• The organizational gross GHG emission (scope 1 and 2) in 2019 was 28,458.54 t-CO2e with the majority (97.7%) coming from scope 2 emissions. Comparing with the base year 2009, the emission level has cut 20,498.6 t-CO2e, equivalent to a reduction of 41.87%.

According to ISO 14064-1, the sources of GIGABYTE’s GHG emissions are as follow:

• Scope 1: Direct emission sources including fuel consumption by company vehicles, emergency generator fuel, LPG used by production processes and cafeteria, refrigerant dissipating from refrigerators and air-conditioners, and septic tanks.

| Gasoline (kl) | Diesel fuel (kl) | LPG (mt) | |

| 2018 | 25.87 | 28.85 | 0.54 |

| 2019 | 17.15 | 26.29 | 0.48 |

• Scope 2: Indirect emissions from externally purchased electricity, heat, or steam. Most of GIGABYTE’s GHG emissions are from scope 2 with the bulk being emissions from electricity consumption.

Energy Consumption

Over the past several years, the total electricity consumption by all four plants of GIGABYTE was around 48,000 to 53,000 MWh per year. After the launch of “Green Action Plan” in 2009, power consumption has gradually decreased each year due to the improvement of manufacturing equipment and energy-saving facilities as well as educating employees to change their behaviors of consuming electricity. The electricity use decreased down to 39,649 MWh in 2019, which was 12,332 MWh less compared to the base year 2009. The electricity use per person went down from 9.64 in 2009 to 7.72 (MWh per person), and the average electricity use per production unit also reduced from 3.35 to 3.21 (kWh per piece).

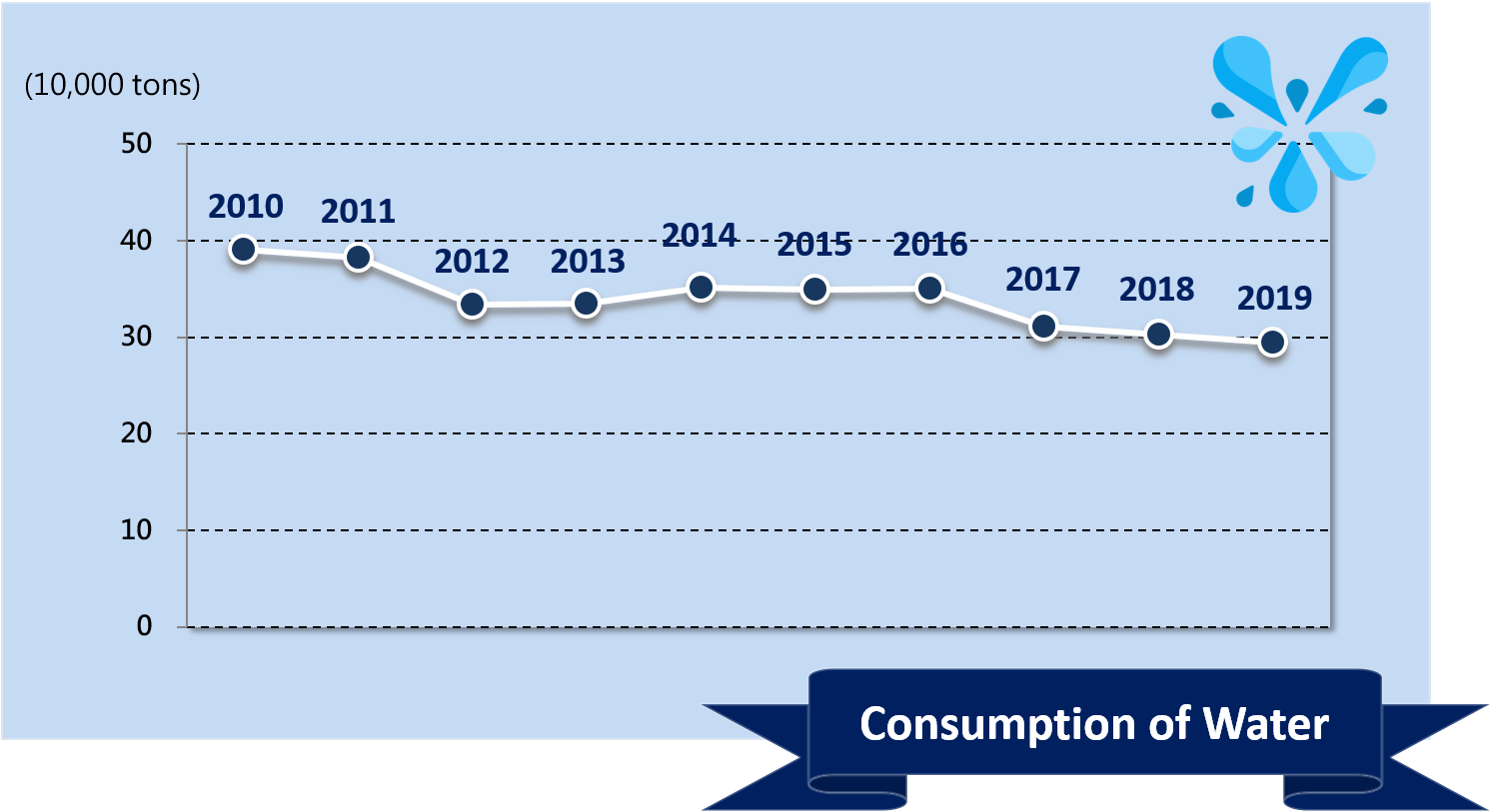

GIGABYTE's main production process does not require water resources. The bulk of water consumption comes from plant infrastructure (e.g. Recycled water for air-conditioning and compressors) as well as employee's domestic water consumption. All water resources come from public utilities. GIGABYTE does not draw upon rivers or ground water directly so causes no significant impact on water sources and community water supplies. Our plants in Taiwan and China used 294.4 thousand tons of water in 2019, which was 24.55% less compared to the total used water amount in the base year 2010. The average water use per person was 57.3 tons, which was 15.69% less compared to that in 2010. As for wastewater management, the total wastewater amount was 251.4 thousand tons in 2019, which was 19.5% less compared to the quantity of 2010.

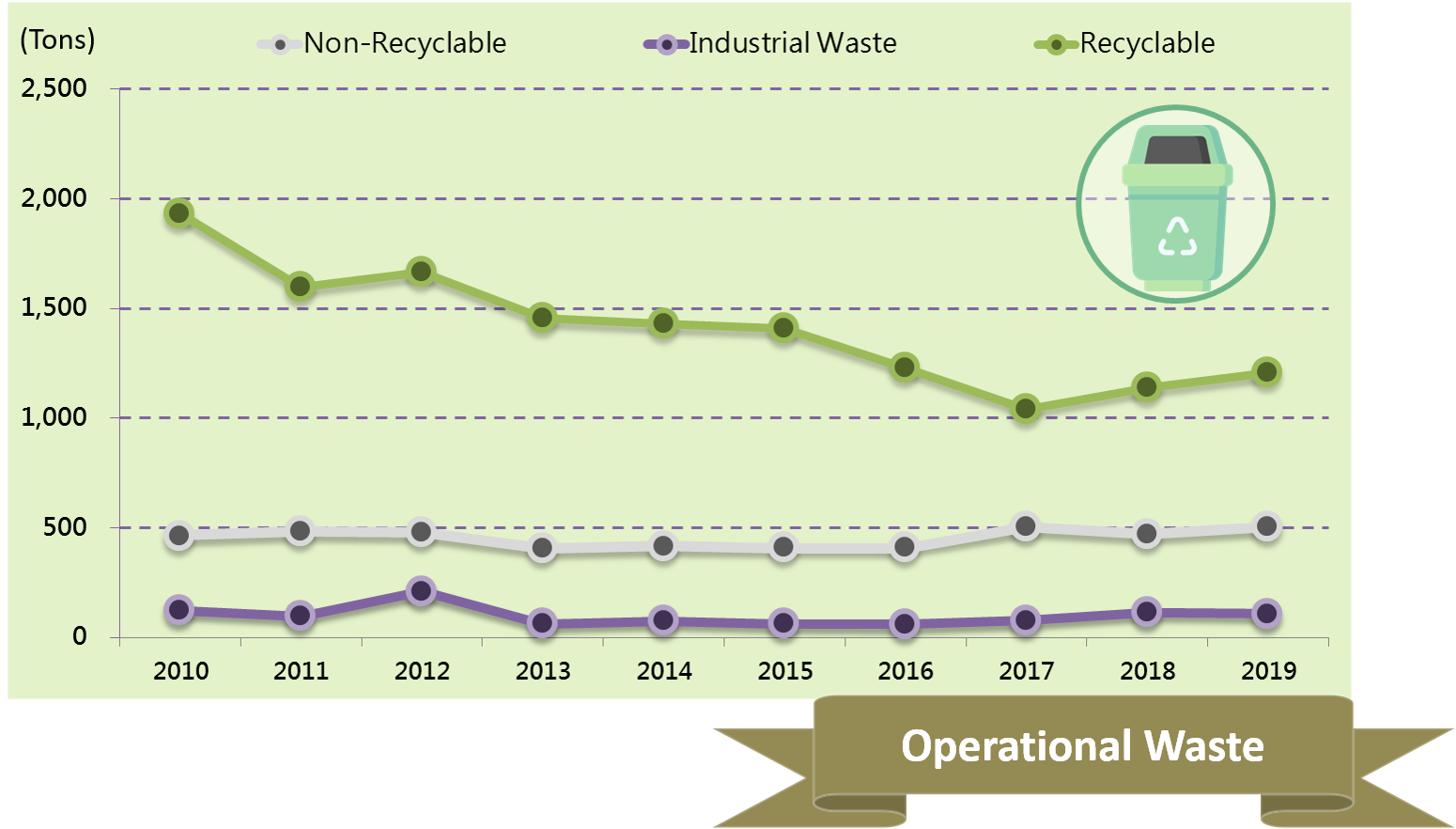

Waste is now treated as resources and managed accordingly through proper sorting at the source to improve the recyclability of waste. GIGABYTE also collaborates with waste disposal and recycling firms to identify and develop potential recycling methods in order to reduce the amount of waste ultimately sent to incinerators and landfills. We also actively work with material suppliers to reduce the amount of chemical use at the source and the generation of waste chemicals. In 2019, we generated 505.73 tons of industrial wastes, 1206.97 tons of recycled waste and 106.51 tons of hazardous waste, which mainly included waste tin and lead sludge, waste metals and waste liquor.